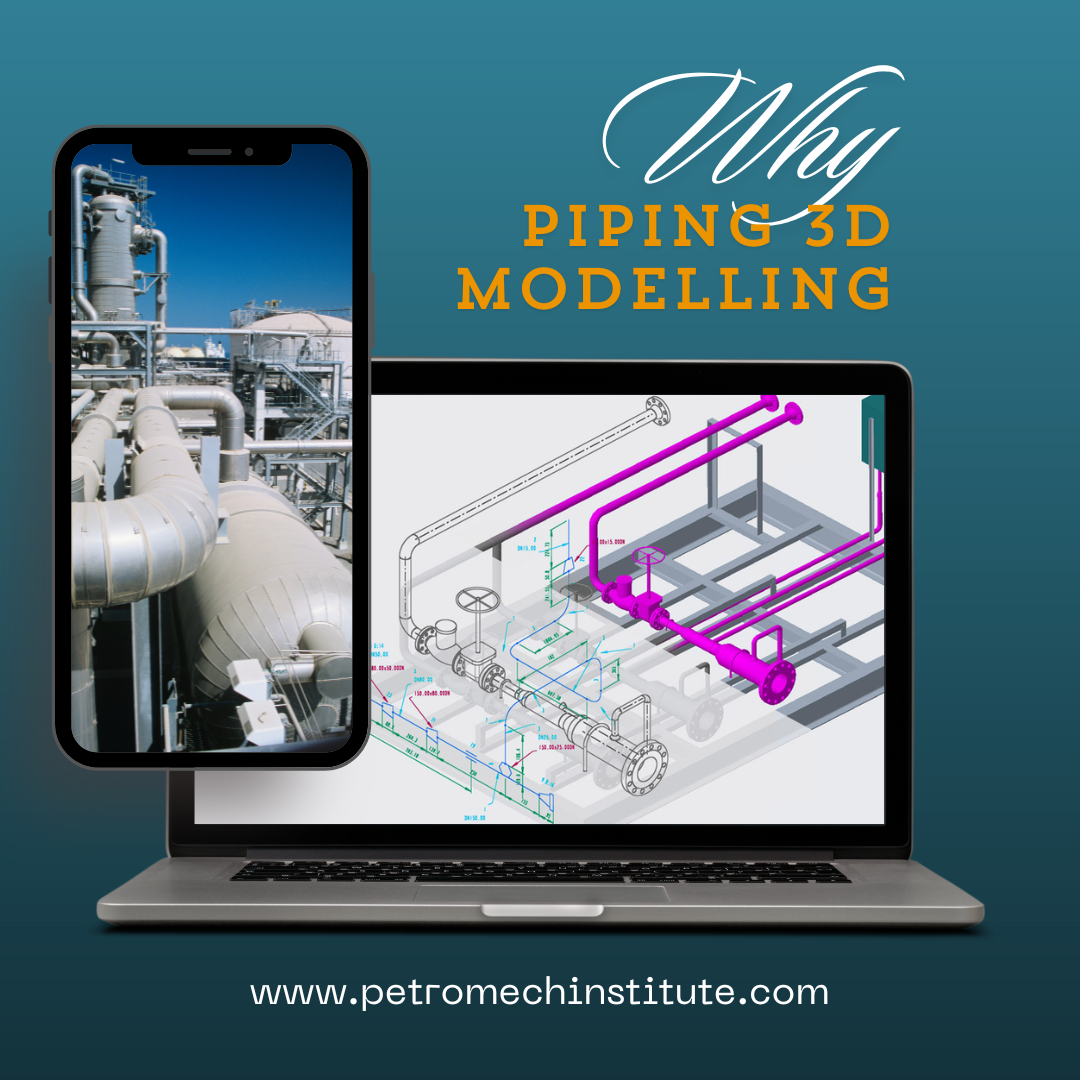

Why Piping 3D Modelling is important?

After completing piping 3D modeling, several important outputs are generated. These outputs are essential for various stages of project execution, from design to construction and maintenance. Here are some key outputs:

1. Isometric Drawings

Isometric drawings offer a three-dimensional representation of the piping system on a two-dimensional plane. The information provided encompasses specific details such as the lengths of pipes, angles, fittings, and equipment. These designs serve the purpose of facilitating the production and installation processes.

2. Piping Layout Drawings

These illustrations depict the comprehensive arrangement of the pipe system within a plant or facility. They encompass the precise positioning of pipes, equipment, and support structures. Piping layout drawings are crucial for strategizing and synchronizing construction operations.

3. BOM (Bill of Materials)

The Bill of Materials (BOM) provides a comprehensive inventory of all the necessary materials, components, and equipment needed for the piping system. The document encompasses quantities, specifications, and occasionally expenses. The Bill of Materials (BOM) is essential for the efficient management of procurement and inventory.

4. 3D Model Renderings

Visual representations of the 3D model are generated to offer an authentic depiction of the piping system. These visual representations are frequently employed for the purpose of delivering presentations, conducting design evaluations, and facilitating communication with stakeholders.

5. Clash-Detection Reports

These reports detect possible conflicts or collisions among pipes, structures, and equipment. To address issues before construction begins, automated clash detection techniques produce the reports.

6. Fabrication and Spool Drawings

Fabrication drawings provide comprehensive instructions for the production of specific components. Spool drawings pertain to the pre-fabricated and assembled portions of piping that are subsequently installed on-site.

7. Construction and Installation Documents

The documents encompass protocols, timetables, and directives pertaining to the building and installation of the piping system. They verify that the project is implemented in accordance with the design standards.